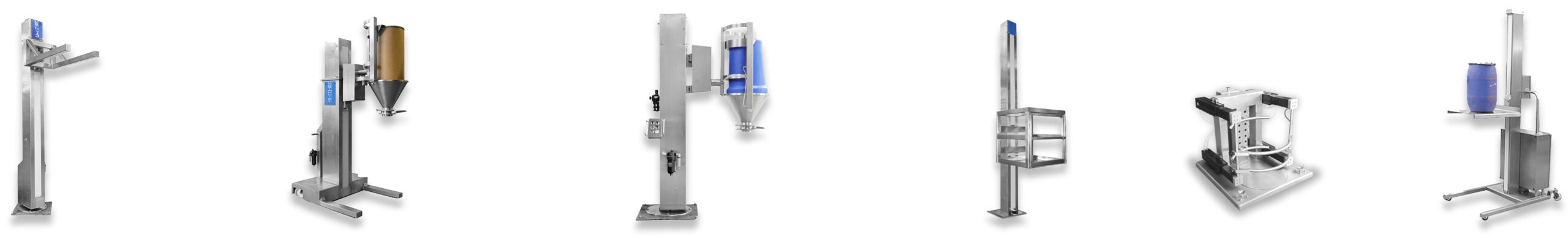

Equipment positioners play a crucial role in optimizing production and manufacturing workflows, ensuring efficiency, precision, and safety. METO Systems offers both mobile and stationary equipment positioners, each designed to meet the unique demands of various industries. But how do you determine which option is best for your operation?

This article will explore the key differences between mobile and stationary equipment positioners, comparing their features, advantages, and best-use scenarios.

Mobile Equipment Positioners: Flexibility & Versatility

Key Features:

- Mobility: Designed for use across multiple destinations within a facility.

- Communication Integration: Can connect with plant control systems.

- Customization Options: Supports integrated weighing operations, XP-rated areas, and specialized lift attachments.

- Rotational Column: Enables precise positioning with a 350-degree arc rotation.

- Fail-Safe Lift Mechanism: Prevents drift, even during power loss.

- Safety Interlocks: Ensures safe operation by enforcing a specific sequence.

- Drive & Control Options: These are available in pneumatic or electric configurations, with manual, semi-automatic, or full automation capabilities.

Best For:

- Facilities requiring equipment mobility between multiple workstations.

- Operations needing flexibility in positioning across various production areas.

- Workflows that demand integration with plant control systems for automated efficiency.

Advantages:

- Increased flexibility for multi-location use.

- Allows on-demand lifting and positioning at different stations.

- Enhances automation and process integration.

Considerations:

- Requires adequate space for movement.

- Higher initial investment due to mobility features.

Stationary Equipment Positioners: Stability & Precision

Key Features:

- Fixed Installation: Ideal for dedicated workstations where mobility isn’t required.

- Communication Integration: Like mobile units, these can also connect with plant control systems.

- Customization Options: Configurable for specific lifting applications, including weighing and XP-rated areas.

- Rotational Column: Supports 350-degree arc rotation for optimal positioning.

- Fail-Safe Lift Mechanism: Ensures lift stability and prevents movement during power loss.

- Safety Interlocks: Enhances operational security with controlled movement sequencing.

- Drive & Control Options: Pneumatic or electric systems with varying automation levels.

Best For:

- Workstations where equipment remains fixed in one location.

- Processes requiring high precision without frequent repositioning.

- Operations with limited floor space, where mobile units may not be practical.

Advantages:

- Stable and precise for consistent workflow needs.

- Lower maintenance due to fewer moving parts.

- Ideal for high-volume, fixed-position processes.

Considerations:

- Less flexibility than mobile units.

- Requires dedicated space for installation.

Making the Right Choice for Your Operation

When deciding between a mobile or stationary equipment positioner, consider:

- Do you need flexibility? → Mobile units allow movement between locations.

- Is precision positioning key? → Stationary units offer stability for fixed applications.

- Do you need plant system integration? → Both options support automation and communication integration.

- What’s your available workspace? → Mobile units require maneuvering space, while stationary units need a dedicated installation area.

Both METO Systems’ mobile and stationary equipment positioners are built for safety, reliability, and efficiency—the best choice depends on your specific operational needs.

Need help choosing the right solution? Contact us today for expert guidance!

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.

If our website does not discuss your specific needs, we invite you to contact us at 201-405-0311. Our skilled engineers are ready to engage in a conversation to understand and address your unique requirements and challenges.