Drum blenders, also known as drum tumblers, are industrial mixing devices that uniformly blend dry powders and granules. They are also commonly used to keep ingredients in liquid suspension and break up powder clumps before discharge.

METO Systems’ sanitary drum blenders are designed to perform these three key activities, but they differ from traditional drum rollers by rotating the drum end over end rather than spinning it around its central axis. This design ensures more effective agitation inside the drum and eliminates the need to lay it on its side.

Versatile Solutions for Multiple Industries

Drum blenders’ applications span various industries, including pharmaceuticals, food processing, chemicals, and cosmetics. In the pharmaceutical industry, drum blenders are essential for mixing dry powders and granules to create tablets, capsules, and other products. In the chemical industry, they play a critical role in blending dry chemicals and compounds to produce a range of products, including detergents and fertilizers. In food processing, drum blenders guarantee the uniformity of ingredients such as flour, spices, and sugar, which helps achieve consistent flavor and quality. In the cosmetics industry, they are used to blend cosmetic powders, pigments, and various ingredients, ensuring product quality and appearance consistency.

How Drum Blenders Improve Manufacturing Efficiency

Drum blenders are designed for easy handling, requiring minimal manual intervention. Their user-friendly design streamlines the blending process, reducing the risk of operator errors and improving overall efficiency.

These blenders provide excellent blending performance, ensuring thorough mixing of powders and granules. The tumbling action facilitates efficient blending, resulting in a homogeneous mix with consistent quality.

Uniform blending of ingredients leads to consistent product quality. The gentle tumbling action prevents particle segregation, ensuring a well-mixed blend.

With the ability to efficiently blend large batches, drum blenders significantly reduce processing time compared to manual or less efficient methods. This not only increases production output but also lowers operational costs.

Despite their advanced capabilities, drum blenders remain a cost-effective option compared to other high-end blending equipment. This makes them an attractive choice for manufacturers seeking to enhance their blending processes without exceeding budget constraints.

Integrating a drum blender into manufacturing operations offers numerous benefits, including versatility, convenient blending containers, economical solutions, and a large capacity range. Manufacturers can greatly benefit from the efficiency and reliability these blenders bring to their processes.

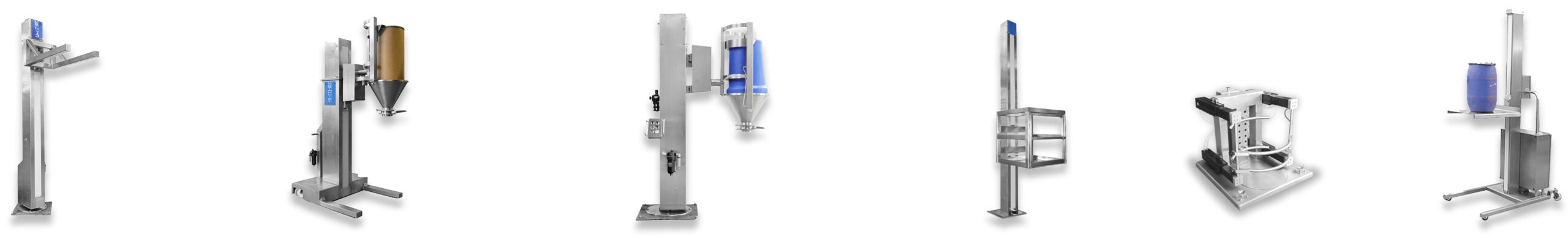

METO Systems drum tumblers are offered in various configurations. Choose between in-place or mobile bases, powered or manual clamping, and PLC or basic pneumatic controls. Custom floor standing units are available with capabilities including vertical lift and the ability to discharge directly from the blended container. Our stainless-steel construction offers a variety of finishes to meet industry hygienic requirements or your unique operational constraints. Many other features and options are also available.

If you’re looking for a drum blending solution to help speed up the production process, METO Systems’ equipment is designed for years of reliable service. It operates with minimal maintenance all day, every day. Contact us to learn more about the advantages of METO Systems drum blenders.

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.

If our website does not discuss your specific needs, we invite you to contact us at 201-405-0311. Our skilled engineers are ready to engage in a conversation to understand and address your unique requirements and challenges.