Large, heavy drums can be cumbersome and even hazardous to maneuver. Having the proper drum handling equipment can mean fewer accidents and a safer work environment for your employees. In this article we will discuss METO Systems’ drum handling equipment along with some of their benefits.

In general, drum handling equipment is specially designed to make the movement and work concerning heavy drums as effortless, safe, and time efficient as possible. The long-term benefits include:

- Greater workplace safety with less accident and incidents related to stress injuries and improper handling accidents, which in turn reduces injury claims and time off from work and instills confidence among employees.

- Improved quality of product with lesser risk of product damage during movement and handling.

- Workers can maximize their work output through faster handling.

- Eliminates the physical strength and endurance that would otherwise be required for a worker to manually handle drums.

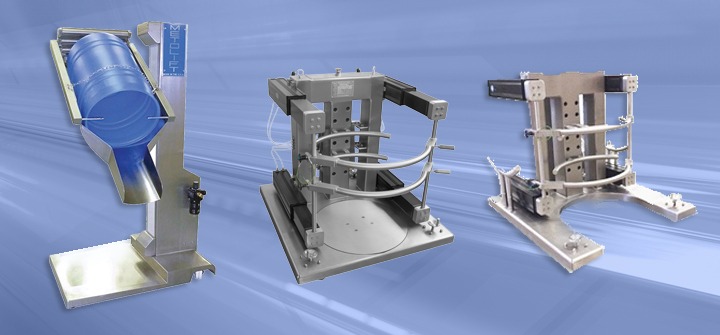

Drum Conditioners, also referred to as Drum Massagers, are used to break up packed or solidified material. When drums of dry powder become interlocked through road transport, heat, humidity or simply over time, it becomes difficult to produce material flow, or sometimes any flow at all. METO Systems drum conditioners are used to squeeze flexible walled drums, bags, and boxes to break up packed or solidified material.

Manufactured from 304 stainless steel, our drum conditioners are fully pneumatic, no hydraulics, and no electrical requirements. It is equipped with a manual turntable to hold the drums, floor locks, two-handed controls for safe operation, and four abrasion-resistant polyurethane wheels to allow for easy maneuverability.

Drum Dumpers, Tilters and Tippers are used in a variety of ways during industrial production. They are ideal for charging coaters; filling hoppers, reactors and other process vessels; dispensing applications; and discharging powders, granules, pellets and tablets. Our patented tilt profile system, and tampered custom chutes allow for ease in charging tablet coaters with vertical charging ports; filling hoppers, reactors and general applications.

Drum Tippers are used to position the drum downward, so the product can be easily discharged through a bung in the head of the drum. They are typically used when drums contain liquid.

Drum Tilters are used to position the drum at an angle to control the discharge of material (usually powders). They work best to provide a slight angle to ease the transition of the material and allow for scooping from the drum. They can also be angled more steeply so substances can be “raked” out as the material is emptied.

Drum Dumpers are typically used to fully empty the contents of a drum containing powders or pellets. Usually, the drum is lifted and then angled above a specific receiving container or piece of processing equipment. They can be configured with or without chutes or cones. Chutes direct an open discharge out and over a receiving port, while cones—when combined with METO Systems’ patented discharge valves—create a closed transfer that enhances dust control.

Regardless of the unit needed, METO Systems’ dumpers, tilters and tippers include stainless steel construction with an upgradable finish; non-marking, white polyolefin wheels; powered floor-locking devices; and mounted, push-button controls. Our fail-safe lift mechanisms hold the lift in position without drift even on loss of utilities.

Sometimes the simplest jobs require the best equipment. If your operation requires the frequent movement and manipulation of heavy drums, consider METO Systems. For nearly 50 years METO has been exceeding the requirements of our customers with long lasting reliable products. Our dedicated staff is here to support you with all your engineering design and installation questions. For more information on our products and services please contact our sales team at 201-405-0311.