Drum Manipulators

Sometimes, simply lifting and dumping isn’t the best way to approach that step in the process. You need a way to accurately position your product as it flows from the drum.

In industries like pharmaceuticals, for example, merely tilting the drum and chute can result in extensive spillage. This is particularly true for operations that load tablets into a coater with a vertical port and deep baffles.

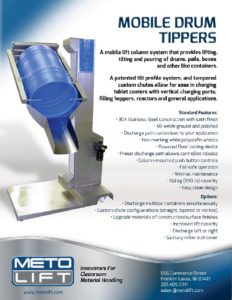

METO Systems’ sanitary drum manipulators are fitted with a patented cam-action lift and tilt, which means they can precisely place the discharge point inside the coater while it lifts the drum to the proper angle for discharge.

Since tilting while lifting and positioning can be risky for both the operator and the product, METO drum manipulators are equipped with powered floor-locking devices, to minimize some of this risk. The mobile base helps ensure fluidity of movement and access to the coater for discharge and maintenance, and white polyolefin wheels protect against marking.

Drum lifter and tilter helps to handle heavy drums in the manufacturing unit efficiently. It not only reduces manual labor but it also reduces any wastage due to spills and such others. METO Systems provide drum inventor, lifter, and tilter with 3 different drives – Pneumatic, Electric, and Hydraulic. These tilters are very easy to install and operate. They are designed to handle drums of different sizes and we offer customizations to suit your business needs.

Call at +201-405-0311 or fill this form to contact us.

Features

- METO Systems’ patented cam-action lift-and-tilt, allows for precise placement of discharge points while lifting to an exact angle

- Mobile base ensures fluidity of movement, maintenance access, and a smooth discharge.

- Customizable discharge paths for specific applications, and chute configurations that can be straight, tapered or necked

- Stainless Steel construction with fine finishes for hygienic drum manipulators.

- Pneumatically driven

- Discharge path customized to your application

- Non-marking, white, polyolefin wheels

- Powered floor locking device

- Minimal maintenance

- Push-button controls mounted on the column

- 150 kg (330lb) capacity

- Custom chute configurations (straight, tapered, necked)

With a discharge path that’s customized to the specific application, and chute configurations that are straight, tapered or necked, the METO sanitary drum manipulator is a favorite with several large contract tablet-coating operations. Likewise, our stainless steel manipulators feature a full range of surface finishes to meet any number of industry standards.

When lifting and dumping just isn’t enough, give us a call to see how our customizable stainless steel drum manipulators can help speed up or improve your production or manufacturing process.