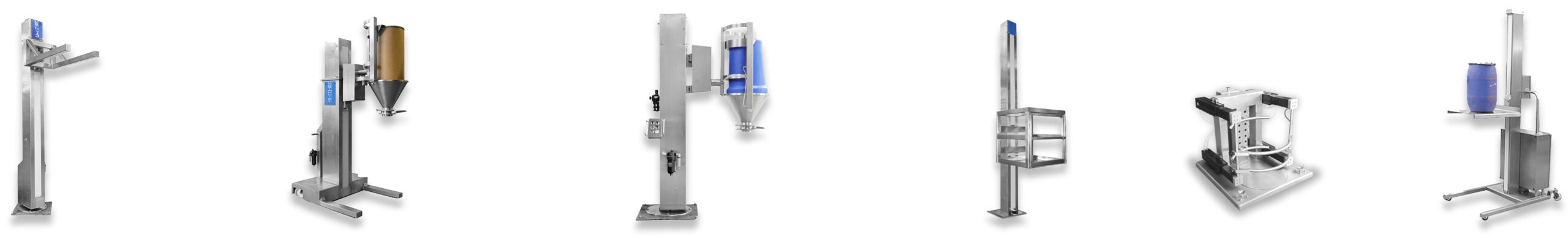

In industries such as pharmaceuticals, nutraceuticals, and food manufacturing, efficient material handling is essential for maintaining productivity, reducing waste, and ensuring safety. One of the most critical aspects of this process is the effective transfer and discharge of powders, liquids, and mixed products from processing equipment. METO Systems’ innovative column bowl lifts offer a seamless, safe, and highly efficient solution for these challenges.

The Need for Bowl Inverters

Most stainless-steel bowl inverters used with mixers, granulators, or fluid bed dryers do not include a bottom discharge outlet. This limitation requires operators to scoop, dump, or manually invert the bowl to remove product, increasing the risk of contamination, product loss, and inefficiencies. METO Systems has developed an advanced line of bowl inverters and tippers designed to keep product flowing while minimizing handling risks and optimizing safety.

Innovative Design and Features

METO Systems column bowl lifts are designed to meet the highest standards of efficiency and safety. Their standout features include:

- Patented Valve Design – Allows for quick changeovers and easy cleaning while effectively controlling the discharge of fine powders, granular products, or tablets.

- Discharge Cone Options – Accommodates both manual and automated clamping for seamless product transfer.

- Fail-Safe Lift Mechanism – Ensures the platform remains securely in position without drift, even during a power outage.

- Integrated Safety Features – Interlocking and sequencing mechanisms prevent accidental operation, protecting both personnel and equipment.

- Customization Options – Available in mobile or stationary configurations, with adjustable height and reach specifications to fit any application.

Comprehensive Specifications

METO Systems’ column bowl lifts are built with premium stainless steel construction and fine finishes to meet the highest hygiene standards. Additional specifications include:

- Drive Options: Pneumatic, Electric, Hydraulic

- Control Systems: 24 VDC electric, basic, semi-automatic, or fully automated via PLC integration

- Operational Safety: Interlocked gates and barriers to enforce safe operation sequences

- Rotational Column Option: Allows for precise positioning during discharge

- Minimized Maintenance Costs: Designed with standard components for ease of maintenance and reduced operational costs

Customization for Specific Industry Needs

METO Systems understands that no two operations are the same. That’s why their column bowl lifts can be tailored to meet specific application requirements, including:

- Explosion-Proof (XP) Rated Options – Designed for hazardous environments.

- Integrated Weighing Systems – Ensuring precise material measurement and handling.

- Flexible Drive Systems – Choose from electric, hydraulic, or pneumatic drives based on operational needs.

- Surface Finish Customization – A full range of stainless steel finishes to comply with industry-specific regulations.

Enhancing Pharmaceutical and Food Production

METO Systems’ column bowl lifts are widely used in pharmaceutical granulation and fluid bed drying processes. The Column Bowl Lift, with a large hopper-bottomed pharmaceutical bowl inverter, is specifically engineered for precision discharge, providing easy clamping, smooth inversion, and a safe handling process for large batches. Its 304 stainless steel construction, powered inversion, and manual or automated discharge valve make it a reliable choice for highly regulated environments.

Why Choose METO Systems?

With a commitment to safety, efficiency, and industry compliance, METO Systems column bowl lifts are the preferred choice for major brands in pharmaceutical, nutraceutical, and food production. Whether you need a standard configuration or a fully customized solution, METO Systems offers durable, high-performance equipment that fits within various budgets and capacities.

Take the next step toward streamlining your operation. Contact METO Systems today to discuss how our column bowl lift can optimize your material handling process!

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.

If our website does not discuss your specific needs, we invite you to contact us at 201-405-0311. Our skilled engineers are ready to engage in a conversation to understand and address your unique requirements and challenges.