Making quick and safe work of moving heavy loads in a sanitary work environment.

Motorized pallet jacks are essential to daily operations in many manufacturing and distribution environments. They can easily lift more than 2,000 pounds, and are often viewed as safer to operate than forklifts.

When purchasing a new powered mobile pallet jack, it is important to familiarize yourself with its design and unique features to operate it properly. Equipment features can vary greatly from manufacturer to manufacturer and pallet jack to pallet jack. Making it unsafe to assume all electric pallet jacks are alike.

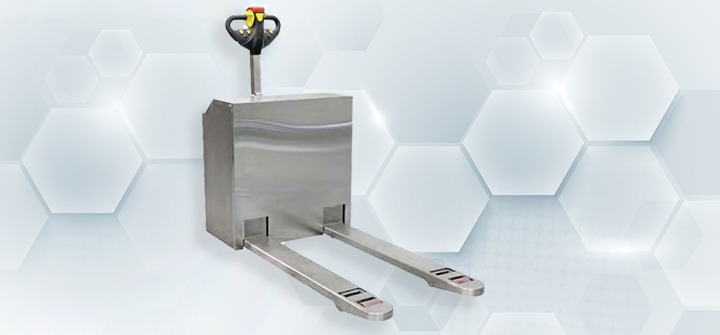

Stainless steel pallet jacks are ideal for pharmaceutical, medical, food, nutritional, and fine chemical environments. Safety should be a top priority and take a lead role when electric pallet jacks are operated in a sanitary environment. The best electric pallet jacks offer features that help improve the physical safety of the operator, including a durable, industrial design with steel frame and panels.

10 tips to keep your workplace safe:

- Perform a basic pallet jack and workplace inspection before using the pallet jack for the first time each workday.

- If any issues or defects are found during the inspection, do not operate the pallet jack and report them to your supervisor immediately.

- Wear the required PPE when operating a pallet jack, i.e., gloves and hard-toe boots.

- Never overload the pallet jack; know the maximum load limit.

- Become familiar with safety features such as direction reverse.

- Maintain your speeds at low levels, moving slowly enough to keep the load under control.

- Watch for clearance on both sides of the load.

- Always stop entirely before changing the direction.

- Park your unused pallet jack on a level surface with the forks lowered.

- Do not store pallet jacks in any area where they block fire extinguishers, emergency equipment, or any exits.

If you are looking for a reliable easy-to-operate pallet mover for your sanitary production facility, look no further than METO Systems. Our pallet jacks are fabricated from 304L stainless steel, designed for cleanroom applications, and can easily lift and move up to 3000 lbs/1361 kg.

Our Powered Mobile Pallet Jack PMPJ efficiency and ease of use make it the ideal solution for transporting bins throughout your sanitary manufacturing process. This versatile, powerful, and compact stacker has a short turning radius, making it the ideal choice for narrow aisles, process suites, airlocks, or where space is at a premium.

Also part of METO Systems’ Powered Mobile Series, the Powered Mobile Straddle Stacker PMSS is versatile, powerful, compact and has a short turning radius, making it the ideal choice for narrow aisles, process suites, airlocks, or where space is at a premium. Perfect for special lift requirements inside clean process areas.

There are few places on the manufacturing or production floor where our Powered Mobile Counterbalanced Stacker PMCS cannot go. The stacker moves, lifts, and lowers efficiently in all manufacturing spaces, but its tight turning radius makes it the ideal choice for narrow aisles, process suites, and airlocks. Regardless of load size, the stacker’s travel speed remains constant relative to the throttle and can maintain high-performance control throughout the entire operation thanks to a 24-Volt Curtis Integrated AC traction and hydraulic system controller.

If you are looking for the operational safety and efficiency only an electric pallet jack can provide, consider a METO Systems powered mobile pallet jack that will reward you with increased productivity and lower costs. Contact us today to learn more.