In industries where efficiency, cleanliness, and precision are essential, the right discharge valve can significantly enhance your process. METO Systems provides a comprehensive range of application-specific discharge valves designed for the Pharmaceutical, Food, Cosmetic, and Fine Chemical industries. Available in both manual and automated configurations, these valves help manufacturers maintain clean, controlled, and efficient material flow throughout their operations.

Let’s explore METO Systems’ core valve technologies and how they support material handling excellence across a wide variety of applications.

Butterfly Valves: A Reliable Workhorse for General Use

Butterfly valves are among the most popular options in process industries due to their durability, simplicity, and ease of maintenance. METO offers a range of butterfly-style valves tailored to specific operational needs:

- Standard Butterfly Valves

Ideal for general flow regulation, these valves are compact, cost-effective, and easy to clean—making them suitable for everyday use in hygienic and industrial settings. - Multi-Vane Butterfly Valves

Designed to improve flow control precision, these valves feature multiple vanes that ensure smoother, more uniform product discharge. They are especially valuable in bulk powder applications where accurate metering is important. - Split Butterfly Valves (SBVs)

For processes requiring high containment, SBVs offer a safe and efficient method for transferring sensitive materials between sealed systems. They are commonly used in pharmaceutical manufacturing to protect both the product and the operator from contamination or exposure.

Iris Valves: Gentle Control for Delicate Materials

Iris valves are the go-to solution for managing fragile or friable products. These valves use a flexible diaphragm or sleeve that contracts and expands to control product flow. Their smooth operation minimizes particle breakage, making them ideal for discharging powders, flakes, or granular materials without damaging the product.

In addition to product integrity, iris valves offer exceptional cleanability and are compatible with hygienic environments.

Slide-Gate and Ball Valves: Additional Options for Flow Isolation and Control

- Slide-Gate Valves

These valves are particularly effective for isolating flow and managing bulk solids. Their sliding mechanism allows for a secure seal and quick shutoff when precise batch control or emergency stopping is needed. - Ball Valves

Known for their durability and tight sealing capabilities, ball valves are often used in applications that demand reliable on/off control. Their spherical closure element provides a consistent seal and can be easily actuated, either manually or automatically.

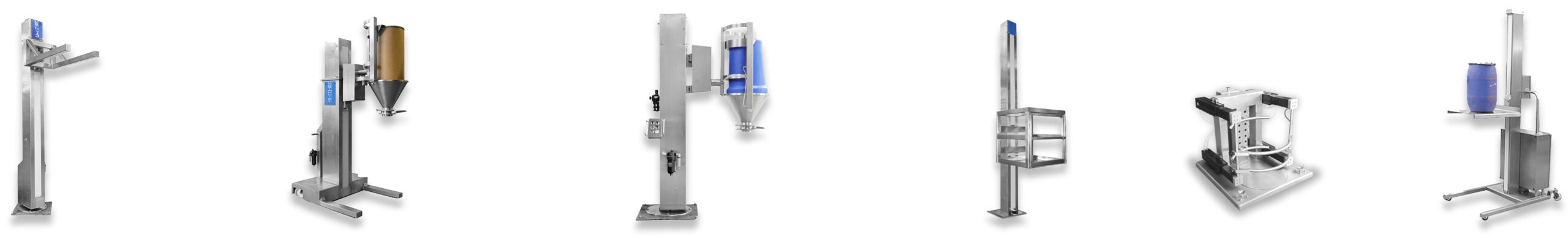

Integrated Solutions with METO Systems

METO’s valves are not just standalone components—they are part of complete material handling solutions. Whether integrated into drum inverters, stationary column lifts, or custom powder transfer systems, these valves ensure that flow control remains efficient, safe, and compliant.

Each solution is engineered with a focus on containment, cleanability, and operator safety, offering peace of mind in even the most demanding manufacturing environments.

The METO Systems Advantage

From butterfly valves to slide-gate, iris, and ball valves, METO Systems offers a full spectrum of discharge control technologies designed to meet the highest standards in regulated industries. Every valve is purpose-built for its intended application, providing precise control over material flow while supporting critical hygiene and containment requirements.

With a commitment to engineering excellence and customer-focused design, METO Systems continues to be a trusted partner in helping manufacturers improve operational performance and product integrity.

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.

If our website does not discuss your specific needs, we invite you to contact us at 201-405-0311. Our skilled engineers are ready to engage in a conversation to understand and address your unique requirements and challenges.