Flexible Intermediate Bulk Containers (FIBCs), or bulk bags, remain an industry-standard solution for the clean, efficient transport and storage of dry materials—ranging from resins and powders to seeds, granules, and pharmaceutical ingredients. Their flexibility, reusability, and low environmental impact make them ideal for sectors with high demands for performance and sustainability.

Why FIBC Bags Still Lead the Way in 2025

FIBC bags offer more than just convenience—they deliver measurable performance benefits:

- Space Efficiency: Unlike rigid bins, FIBCs conform to their contents and can be packed to full capacity. They also fold flat when empty, conserving valuable warehouse space.

- Durability & Reusability: Designed to withstand heavy use, FIBCs resist stretching, shrinking, and weather exposure. With proper inspection and handling, they can be safely reused, reducing packaging costs.

- Sustainability: With more companies adopting eco-conscious supply chain practices, FIBCs are gaining ground as a recyclable, low-impact packaging solution.

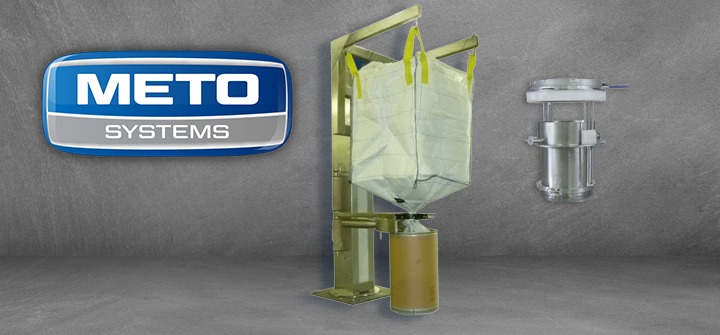

Unlocking Full Potential with METO’s FIBC Docking System

To truly maximize the benefits of bulk bags, pairing them with the right discharge system is critical. Traditional FIBC systems often rely on large, fixed frames and conveyor transitions, increasing contamination risks, cleaning time, and operational inefficiencies.

METO Systems’ FIBC Docking System is engineered to simplify the process—offering direct, gravity-fed product discharge into downstream equipment. Constructed from durable stainless steel and built for cleanroom compatibility, this system features:

- Iris Valve and Inflatable Seal for precision flow control and high-containment transfer

- Minimal Product Contact Surfaces to reduce cleaning and changeover times

- Optional Dust Extraction System for enhanced safety and containment

Pair with METOLIFT™ for Full System Integration

For even greater efficiency, METO’s Column Lifters (METOLIFT) can be paired with the docking system to safely and precisely position FIBC bags. This combination streamlines operations, cuts down on manual handling, and optimizes floor space—perfect for facilities focused on lean manufacturing.

MetoFit™ The Low-Ceiling Column Lift Solution

Recognizing that not all facilities have the luxury of high ceilings, METO Systems developed the MetoFit™ Low-Ceiling Bulk Bag Column Lift—a breakthrough designed specifically for environments with restricted headroom.

Whether you’re working in a compact food production facility, pharmaceutical plant, or a high-end chemical operation, MetoFit eliminates the safety concerns and productivity bottlenecks that come with traditional hoist-and-frame lifting systems.

MetoFit is a prime example of METO’s commitment to innovation, ensuring that even space-constrained facilities can adopt the most advanced bulk material handling technology.

Tailored Valve Systems for Any Process

METO offers a full range of application-specific valves to ensure safe, accurate control of material flow. Available in manual or automated configurations, options include:

- Butterfly Valves

- Multi-Vane Butterfly Valves

- Split Butterfly Valves

- Slide-Gate Valves

- Ball Valves

These solutions are designed for the demands of pharmaceutical, food, and fine chemical manufacturing environments.

If you’re ready to enhance productivity, improve safety, and support your sustainability goals, METO Systems is here to help. From flexible packaging to space-saving lifts and cleanroom-compatible docking systems, our solutions are built to perform.

📞 Call 201-405-0311 or visit our contact page to explore how MetoFit™ and our full line of bulk bag handling systems can transform your process.

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.

If our website does not discuss your specific needs, we invite you to contact us at 201-405-0311. Our skilled engineers are ready to engage in a conversation to understand and address your unique requirements and challenges.