Our blending equipment will ensure that the process is carried out quickly, and as hygienically as possible.

Blending comes with the risk of inconsistency, cross-contamination, product exposure, and loss, but METO Blending System brings you a range of efficient stainless steel blenders.

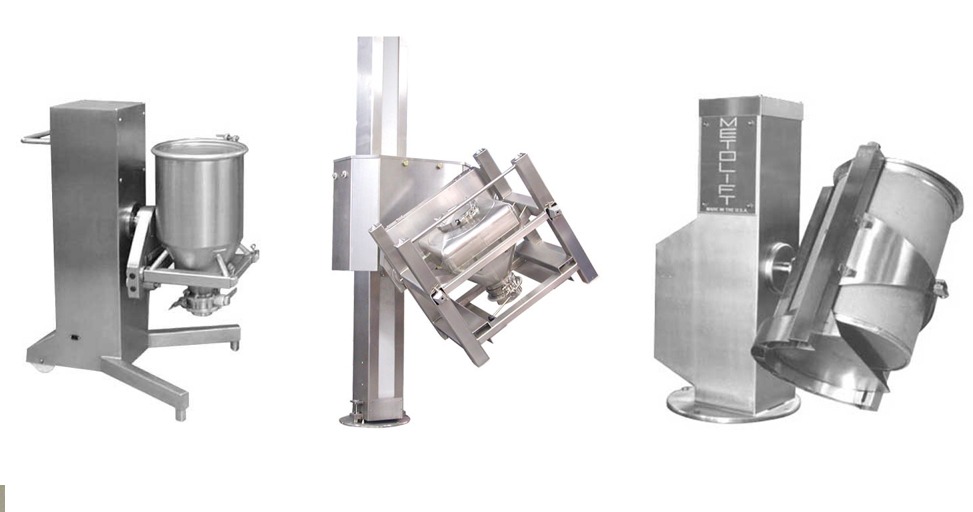

Drum tumbling is a common way to keep ingredients in liquid suspension and to break up powder clumps prior to discharge. It’s also a standard way to simply mix ingredients. When it comes to drum blenders, you want something that most effectively mixes the ingredients on a day to day basis, with minimal downtime required. Our drum blenders work in an end to end motion instead of merely rotating, thereby ensuring consistent mixing. In other words, they differ from more common drum rollers in that they rotate the drum end over end instead of spinning about the center axis. This ensures a more robust agitation action inside the drum and eliminates the need to position it on its side. Crafted in stainless steel construction, with a variety of finishes, base configurations, and control options, our drum blenders are guaranteed to complete the job as smoothly and effectively as possible.

When it comes to lab scale blenders, you want something that prevents product exposure, cross-contamination, and product loss, which is ideal criterion for when handling high-potency materials. Our lab scale blenders are of a fixed height and facilitate safe blending with their full-locking swivel casters and floor-leveling locks. They also minimize space requirements in your facility because they can blend, lift and position right onto a Lift Column. This allows the product to be blended and discharged directly to the next stage of the process, without the need for additional handling. Plus, our fail-safe lift mechanisms hold the platform in place, even in the event of a power loss. Our shining stainless steal lab scale blenders are guaranteed to save you time, energy, and money, as they are designed to complete the job in the upmost hygienic, safe, and sensible manner.

Our bin blenders are similarly designed for high potency material, as the intent is to prevent product exposure, cross-contamination, and product loss. As with Lab Scale Blenders, our bin blenders minimize space requirements in your facility because they can blend, lift and position right onto a lift column. This element allows the product to be blended and discharged directly to the next stage of the process, without the need for additional handling. The same can be done using drums and other types of product containers and our bin blenders can be supplied to mate with existing bins as well.

If you are looking for a system for blending online, then METO System blending machines, designed merely with the standards components, would be the ideal choice for you. As always, our products are made of the highest-quality material and can withstand the test of time, with very little intervention necessary.

*Any necessary support structure or safety supports has been removed from this picture for clarity please reach out to Meto Systems for more information.