About Tumble Blenders

Tumble Blenders, also known as drum blenders, are widely used in the pharmaceutical industry, food industry, chemical industry, and electron industry to mix dry powder. Especially for materials with a high-quality mix demand or multi-product, multi-volume blends.

How Tumble Blenders are used

The most common of all processes is to dry blend powders. This process can be found in the pharmaceutical industry to produce tablets and capsules, the healthcare industry to produce vitamin pouches, and multi-dose supplements, mineral blends to enhance other products, as well as various solid food applications like energy bars or dietary supplements. There are many more applications that don’t only rely on blending quality but look to IBC tumble blenders to reduce washing downtime or reduce contamination or even cross-contamination. Industries in the field of plastics, metal powders, chemicals, pigments, cosmetics, food, pyrotechnics, etc can all benefit.

Some formulations can involve the fine blending of as many as 40-50 components. The size and density of these components can be vastly different and in some cases, multiple “pre- blends” and frequent testing are required, creating a time-consuming and costly process.

To resolve this, manufacturers require high-volume precision blending of formulations on equipment that provides exceptional batch-to-batch consistency and repeatable results. Among the available options is tumble blending equipment that can be engineered to meet the specific requirements of the application. Drum tumbling is a common way to keep ingredients in suspension and to break up powder clumps prior to discharge. It’s also a standard way to simply mix ingredients.

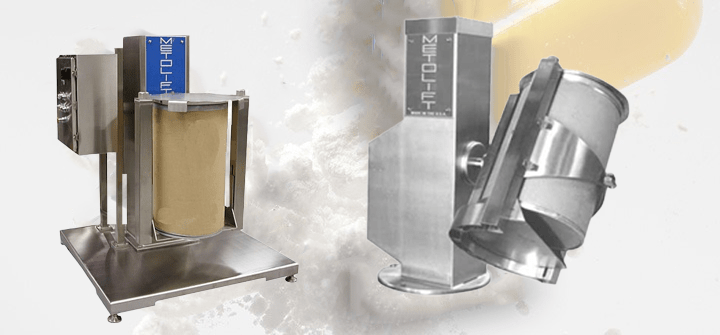

METO Blending Systems

METO Systems’ sanitary drum tumblers work for all three activities, but they differ from more common drum rollers in that they rotate the drum end over end instead of spinning about the center axis. This ensures a more robust agitation action inside the drum and eliminates the need to position it on its side.

In general, blending comes with the risk of inconsistency, cross-contamination, product exposure, and loss but METO blending systems bring you a range of efficient stainless-steel container blenders that ensure the process is carried out quickly guaranteeing safety and hygiene. With the aim to effectively mix the ingredients, the drum blenders work in an end-to-end motion instead of merely rotating, thereby ensuring consistent mixing. The lab-scale blenders are of a fixed height and facilitate safe blending with its full locking swivel casters and floor leveling locks. The bin blenders are designed for high potency material, and they can be supplied to mate with the existing bins.

Our blending equipment is designed for a lifetime of reliable service. It is robust, value-engineered, and delivered as a complete system with little to no need for on-site assembly. Our engineering and service departments are available to provide systems support and advice on upgrades or maintenance and don’t forget our parts department for all spares requests.

For more information about our products and services please contact our sales team at 201-405-0311 or visit our contact page.

*Any necessary support structure or safety supports has been removed from this picture for clarity please reach out to Meto Systems for more information.