Powder flow problems can cause frustration and create backups resulting in expensive downtime and the production of substandard products. Powders can act like solids and liquids and lead to product flow issues. Flow issues can result from a product’s handling, storage, and uniform processing, including too much or insufficient blending.

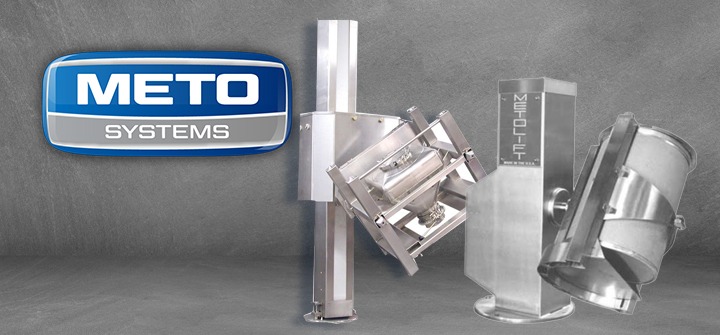

Efficient and safe material handling is critical in pharmaceutical, nutritional, and fine chemical manufacturing. METO Systems’ custom drum inverters provide a reliable solution for transferring powders, pellets, and tablets from drums to downstream processes with precision, safety, and minimal product loss.

Drum handling equipment, including drum dumpers, tilters, and tippers, ensures the safe, reliable, and controlled transfer of bulk materials from drums into downstream processing equipment or storage vessels. The right drum handling solutions can mitigate processing issues, enhance workplace safety, and boost productivity.

For many manufacturers, choosing between available stock equipment and waiting for custom material handling equipment has become a familiar dilemma. While standard machinery may seem quicker or cheaper, production equipment is a decades-long investment. The wrong fit can mean inefficiency, higher costs, and safety risks that compound over time.

In industries such as pharmaceuticals, fine chemicals, and nutraceuticals, precision in dry processing and bulk solids handling is critical. Consistency, safety, and product quality depend on advanced blending technology that can keep up with evolving production demands. Companies are increasingly investing in automated and reliable systems to ensure efficient workflows, safeguard materials, and maintain the highest levels of compliance.

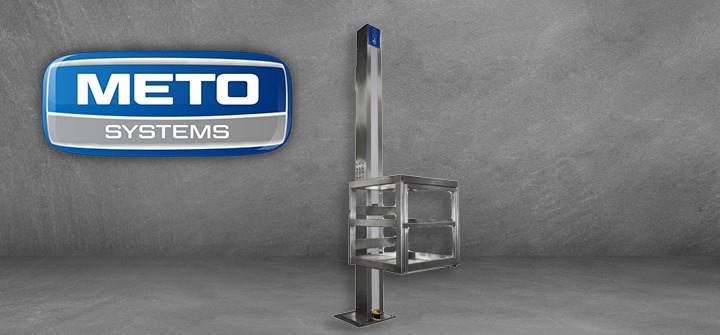

In today’s manufacturing and processing environments, safety and efficiency aren’t optional — they’re essential. The challenge is finding equipment that not only meets the rigorous demands of material handling but also supports hygienic operations. That’s where METO Systems’ Stationary Column Lifts for clean process areas deliver a competitive advantage.

In modern powder processing, IBC bin blending has emerged as a preferred solution for industries seeking higher efficiency, improved hygiene, and better blend integrity. Compared to traditional fixed-shell blenders such as V-cone, double-cone, or ribbon mixers, IBC blenders deliver operational flexibility, faster changeovers, and a cleaner manufacturing process.

When it comes to storing and transporting liquids, powders, or semi-solids, not all containers are created equal. Stainless steel Intermediate Bulk Containers (IBCs) offer a durable, hygienic, and cost-effective solution trusted by industries ranging from pharmaceuticals to agriculture.

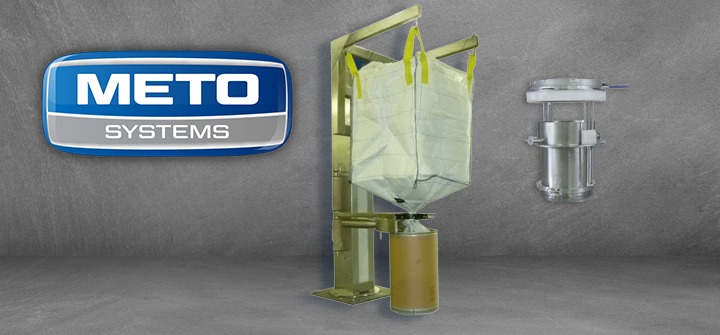

Flexible Intermediate Bulk Containers (FIBCs), or bulk bags, remain an industry-standard solution for the clean, efficient transport and storage of dry materials—ranging from resins and powders to seeds, granules, and pharmaceutical ingredients. Their flexibility, reusability, and low environmental impact make them ideal for sectors with high demands for performance and sustainability.

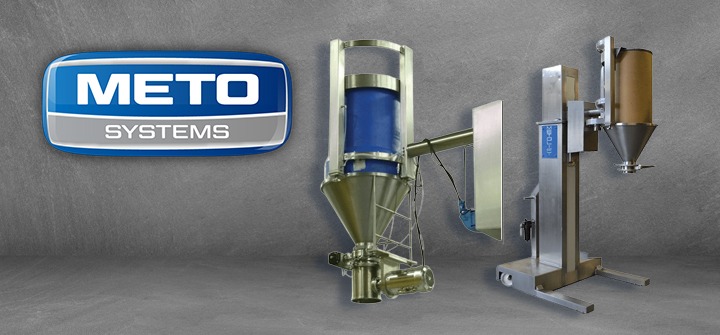

In industries where efficiency, cleanliness, and precision are essential, the right discharge valve can significantly enhance your process. METO Systems provides a comprehensive range of application-specific discharge valves designed for the Pharmaceutical, Food, Cosmetic, and Fine Chemical industries. Available in both manual and automated configurations, these valves help manufacturers maintain clean, controlled, and efficient material flow throughout their operations.