Drum handling equipment, including drum dumpers, tilters, and tippers, ensures the safe, reliable, and controlled transfer of bulk materials from drums into downstream processing equipment or storage vessels. The right drum handling solutions can mitigate processing issues, enhance workplace safety, and boost productivity.

In this article, we delve into the world of drum dumpers, tilters, and tippers, exploring the innovative solutions offered by METO Systems and their myriad benefits.

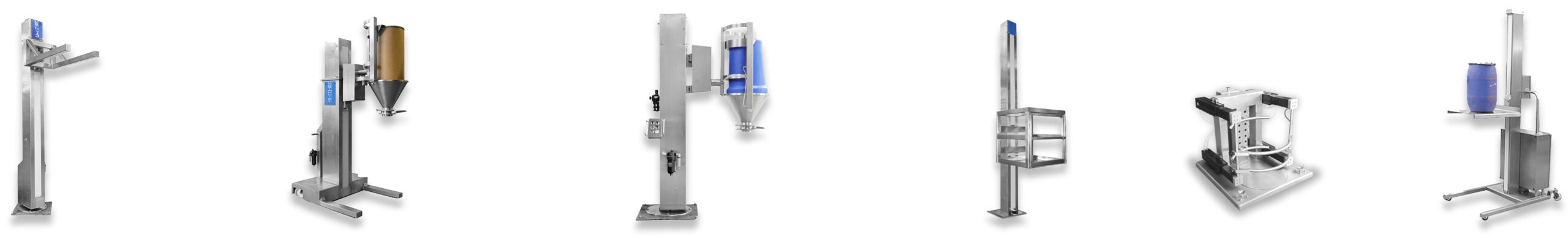

Let’s take a closer look at some of the key offerings from METO Systems:

Drum Dumpers, Tilters, and Tippers

Versatile and adaptable, drum dumpers, tilters, and tippers serve many purposes across industrial applications. Whether charging coaters, filling hoppers, or dispensing various materials, these devices offer unparalleled convenience and efficiency.

Tippers position the drum downward, allowing the product to be easily discharged through a bung in the head of the drum. Stainless steel tippers are typically used when drums contain liquid.

Tilters position the drum at an angle to control the discharge of material. Stainless steel tilters work best to provide a slight angle to ease the transition of the material and allow for scooping from the drum. They can also be angled more steeply so substances can be “raked” out as the material is emptied.

Dumpers are used to fully empty the contents of a drum containing powders or pellets. The drum is lifted and then angled above a specific receiving container or piece of processing equipment. Our stainless-steel dumpers can be configured with or without chutes or cones.

METO Systems’ patented tilt profile system and customized chutes facilitate seamless charging and filling operations. Drum dumpers are ideal for fully emptying drums containing powders or pellets, while tilters and tippers provide precise control over material discharge, catering to both liquid and solid substances.

Constructed from robust stainless steel, METO Systems’ dumpers, tilters, and tippers are highly customizable and sanitary, making them ideal for clean room operations of all types. These products ensure reliable performance and longevity.

In conclusion, investing in high-quality drum handling equipment, such as the solutions offered by METO Systems, is essential for enhancing workplace safety, improving product quality, and maximizing productivity. With their innovative designs and user-friendly features, METO Systems’ drum dumpers, tilters, and tippers are indispensable assets for any industrial operation seeking to optimize efficiency and safety.

About METO Systems

For more than 50 years, METO Systems has been a leading supplier of process and material handling equipment for a variety of industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.

If your specific needs are not discussed on our website, we invite you to get in touch with us at 201-405-0311 or visit our Contact Us page. Our skilled engineers are ready to engage in a conversation to understand and address your unique requirements and challenges.