Drum Conditioners

Having a well-designed Drum Conditioner is essential for safely removing the hardened product from drums or boxes in the dry processing and bulk solids handling industry

Drum Conditioners also referred to as Drum Massagers, are used to break up packed or solidified material. When drums of dry powder become interlocked through road transport, heat, humidity, or simply from storage over time, it becomes difficult to produce material flow, or sometimes, any flow at all. Drum conditioners apply pressure through horizontal and vertical bars to squeeze and break up the crusted or lumpy, dry powders and provide free-flowing product from the drum to downstream equipment.

According to METO Systems, a leading supplier of process and material handling equipment, making a major purchasing decision, such as one for a Drum Conditioner, can be difficult. That is why our fully qualified and factory-trained service personnel provide our clients with the personalized assistance needed to make the perfect product selections for their business needs. We can custom design crushing bars, including straight crush bars for box handling and square angle, vertical crush bars to increase applied pressure for heavy-duty applications.

About METO Systems Drum Conditioners

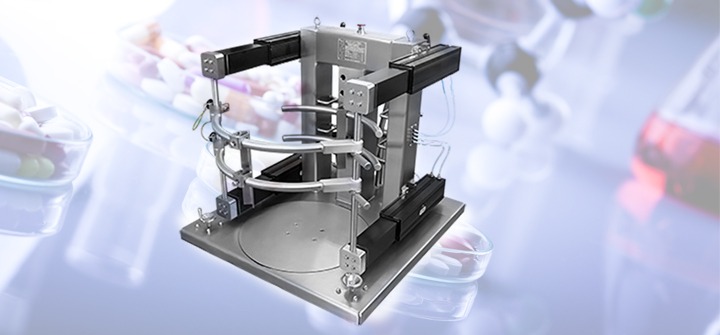

Our drum conditioners are manufactured from 304 stainless steel and are fully pneumatic. They are equipped with a manual turntable to hold the drums, floor locks, two-handed controls for safe operation, and four abrasion-resistant polyurethane wheels for maneuverability. Perfect for use in warehouse environments, cGMP areas, hazardous locations, or any site with an air supply.

Their pneumatic cylinders generate 1600 pounds of clamping force spread evenly yet through multiple points of contact over the drum surface. The turn-table can hold plastic and fiber drums ranging from 12” to 36” in height, and 12” to 22” in diameter; cardboard boxes ranging from 12” to 24” in the square base area, and 12” to 36” in height; and multi-ply paper or plastic bags ranging from 12” to 36” in height.

Our open front unit provides the exact same conditions and benefits as the standard unit, described above with the same crushing force and the same horizontal and vertical bars. However, the open entry drum conditioner works better for applications requiring the unit to operate with the drums still on their dollys. The onboard turntable has been removed in this model, making way for a wheeled dolly and drum.

Expert Installation Services

We help our clients with setup (on-site installation), machinery start-up, operation training, and equipment validation testing. Additionally, we feel it’s important to provide continuous on-site support to our clients to ensure maximum utilization and smooth functioning of our material handling solutions.

Lastly, our equipment is designed for a lifetime of reliable service. It is robust, value-engineered, and delivered as a complete system with little to no need for on-site assembly. Our engineering and service departments are available to provide systems support and advice on upgrades or maintenance and don’t forget our parts department for all spares requests.

For more information about our products and services please contact our sales team at 201-405-0311 or visit our contact page.