Drum Manipulation Equipment

As commonplace as drum manipulation is in today’s industrial workplaces, choosing the wrong type of drum handling equipment can become a very costly mistake. Special lifting devices make it easy to pick up, tilt, rotate, and transport drums. This drum manipulation equipment not only protects employees from physical harm, but also increases the efficiency of the workflow as a whole.

Businesses producing foods, pharmaceuticals, nutraceuticals, cosmetics, or other chemical substances have to store a diverse range of drums filled with various liquids and/or powders. Throughout the manufacturing processes, these drums need to be lifted, tilted and emptied into machines or filling lines. Such operations pose a considerable challenge, as one drum can weigh anywhere from 50 to 500 pounds. Which makes it physically impossible to rely on manual labor to manipulate drums during the manufacturing process.

Transporting Drums

Drum Transporters allow workers to easily move drums ergonomically, eliminating operator strain. At METO Systems we design our drum transporters to be versatile, able to move into tight spots while handling a wide range of weights and drum sizes. They feature a passive grasp system and a manually operated hydraulic lift, therefore, our drum transports require no independent power source. Constructed of stainless steel they are deal for clean-room environments and are reliable for daily use all year round.

Emptying Drums Overhead?

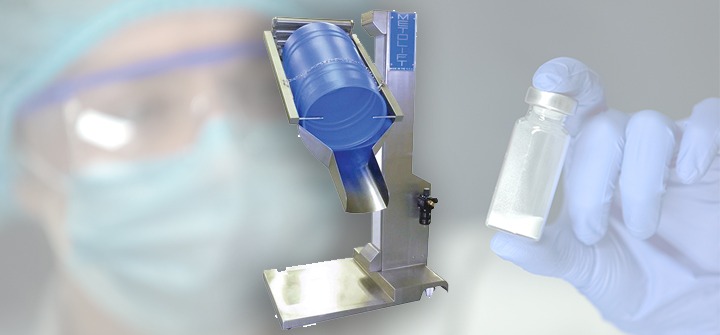

Drum Dumpers and Tippers are an integral part of the industrial production process and are ideal for charging coaters; filling hoppers, reactors, and other process vessels; dispensing applications; and discharging powders, granules, pellets, and tablets.

Tippers are used to position the drum downward, so the product can be easily discharged through a bung in the head of the drum. Stainless steel tippers are typically used when drums contain liquid.

Tilters are used to position the drum at an angle to control the discharge of material (usually powders). Stainless steel tilters work best to provide a slight angle to ease the transition of the material and allow for scooping from the drum. They can also be angled more steeply so substances can be “raked” out as the material is emptied.

Dumpers are typically used to fully empty the contents of a drum containing powders or pellets. Usually, the drum is lifted and then angled above a specific receiving container or piece of processing equipment.

Our stainless-steel dumpers can be configured with or without chutes or cones. Chutes direct an open discharge out and over a receiving port, while cones when combined with METO Systems’ patented discharge valves, create a closed transfer that enhances dust control.

Our patented tilt profile system and tapered custom chutes allow for ease in charging tablet coaters with vertical charging ports; filling hoppers, reactors, and general applications.

Regardless of the unit you choose, METO Systems’ transporters, dumpers, tilters and tippers include stainless-steel construction, most with an upgradable finish; non-marking, white polyolefin wheels; powered floor-locking devices; and mounted push-button controls.

Sometimes the simplest jobs require the best equipment. If your operation requires the frequent movement and manipulation of heavy drums, consider METO Systems. For nearly 50 years METO has been exceeding the requirements of our customers with long-lasting reliable products. Our dedicated staff is here to support you with all your engineering design and installation questions. For more information on our products and services please contact our sales team at 201-405-0311.

*Any necessary support structure or safety supports has been removed from this picture for clarity please reach out to Meto Systems for more information.